Polyfit: Your Partner in Comprehensive Electronics Manufacturing Services (EMS) and Surface Mount Technology (SMT) solutions

Polyfit is an A‑Level SQ‑certified company offering state‑of‑the‑art Electronics Manufacturing Services (EMS) under a controlled Class 10K (ISO 7) cleanroom environment. Our advanced facilities are designed to meet the growing demand for high‑precision Surface‑Mount Technology (SMT) assembly, through‑hole soldering, and comprehensive electronic product manufacturing.

Polyfit is a A-Level SQ Certified Company

Injection Moulding

Polyfit offers advanced injection moulding solutions for a wide range of product sizes and complexities.

Our capabilities include:

- Horizontal, vertical, two-platen, twin-color, and all-electric machines

- Fully automated robotics for consistent, efficient production

- AI-powered vision systems for real-time defect detection

- Centralized raw material feeding with auto-dehumidifiers for optimal quality

Our streamlined shop floor features calibrated auxiliary systems, tonnage-specific cranes, and SMED practices for fast, efficient tool changes.

Pad Printing

Pad printing is an efficient method for transferring 2D images onto 3D automotive parts, including curved and irregular surfaces. It delivers sharp detail, vibrant color, and strong adhesion using specialized inks suited to various materials.

A soft silicone pad adapts to complex shapes for precise image transfer. This process is ideal for branding, markings, and customization.

High-performance pad printing machines ensure consistent quality, excellent registration, and durability—making them essential for demanding automotive applications.

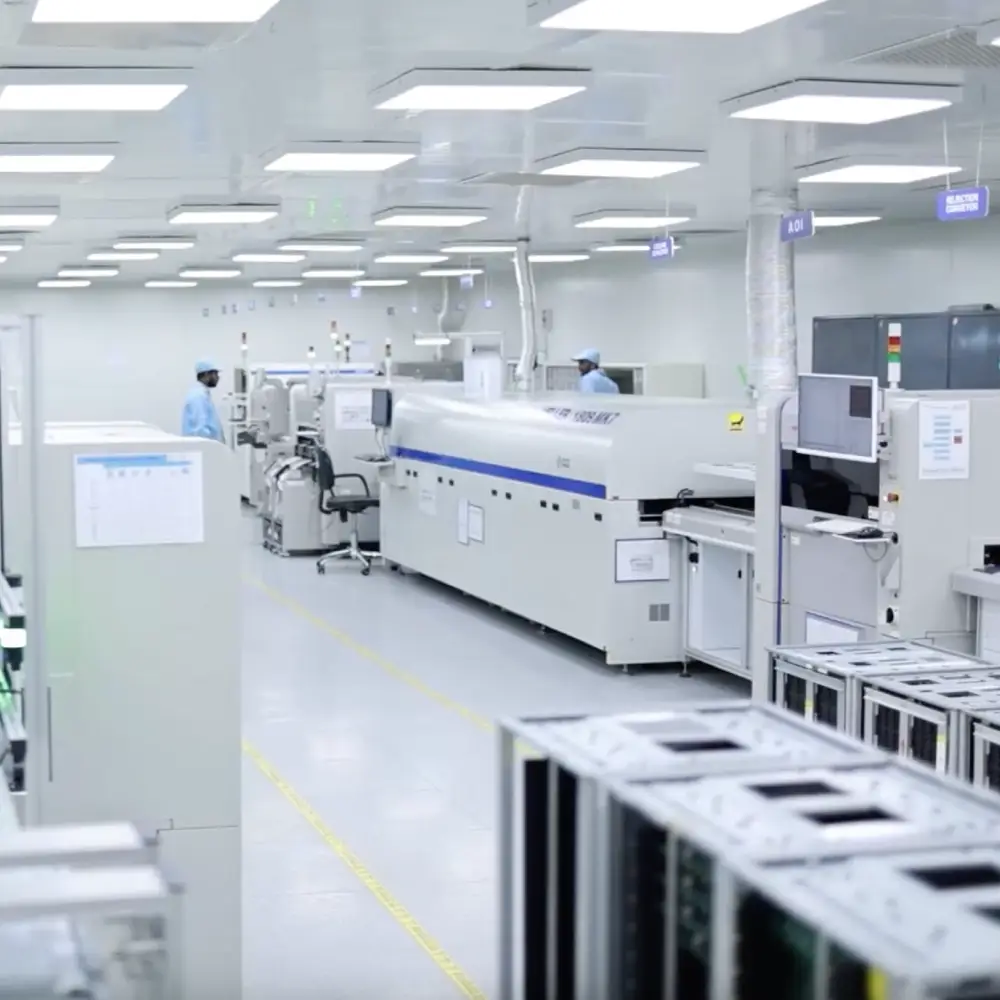

Surface Mount Technology

Surface‑Mount Technology (SMT) involves mounting electronic components directly onto printed circuit boards (PCBs) with exceptional precision.

At Polyfit, our Class 10K cleanroom houses a fully automated SMT production line featuring high‑speed pick‑and‑place machines capable of placing up to 90,000 components per hour. Our process includes solder‑paste inspection (SPI), automated‑optical inspection (AOI), and an auto‑rejection conveyor system to ensure continuous, uncompromised quality control throughout the production cycle.

Our Services

PCB Assembly

Using advanced equipment and techniques, we provide precise and efficient PCB assembly, including SMT, through-hole, and mixed technology assemblies.

Quality and Testing

Supply Chain Management

Production Flexibility

From rapid prototyping to full‑scale production, our flexible systems handle both low‑volume and high‑volume manufacturing efficiently and accurately. We provide comprehensive support across every stage — from component sourcing and design validation to assembly, testing, and packaging.

Aftermarket Services

Class 10K Cleanroom Environment

Our Class 10K (ISO 7) cleanroom ensures that airborne particle concentration remains below 10,000 particles per cubic foot, protecting sensitive electronic components from contamination. The environment maintains controlled temperature, humidity, and electrostatic discharge (ESD) protection, ensuring consistent soldering quality and long‑term product reliability.

Why choose us?

Experienced Team

A‑Level SQ‑certified company with decades of manufacturing excellence

Cutting-Edge Technology

ISO 7 cleanroom for contamination‑free SMT operations

Custom Solutions

Automated SPI, AOI, and rejection conveyor for real‑time quality assurance

Commitment to Sustainability:

End‑to‑end EMS services from prototyping to production

Skilled Technical

Skilled technical team trained in IPC and ESD practices

Global Customer

Proven reliability and global customer base

Comprehensive EMS Support

We offer a complete range of EMS solutions, including PCB assembly, functional testing, conformal coating, box build, and supply‑chain management. Our systems are compliant with Moisture Sensitivity Level (MSL) handling standards, ensuring the safe storage and processing of sensitive components. We turn your ideas into reality — supporting every stage of product development and manufacturing, from concept design to mass production and delivery.

World-Class Electronics Manufacturing Services Across All Industries

Polyfit provides world‑class EMS solutions to a diverse range of industries, including automotive, medical devices, industrial automation, consumer electronics, energy systems, and defense electronics.

Ready to experience high‑precision electronics manufacturing? Contact us today to discuss your EMS requirements

Call us at +91 9551955590 or email us at info@polyfit.co.in