PTFE HOSE

We specialize in providing durable PTFE HOSE solutions known for their superior chemical resistance, high-temperature tolerance, and flexibility, ideal for demanding industrial applications. Beyond PTFE HOSE, our extensive inventory includes a wide range of hydraulic fittings, adapters, and custom hose assemblies, all meeting stringent industry standards to ensure optimal performance and reliability for our clients with Polyfit Industries LLC.

Ready to experience the best in PTFE Hose?

More Info

What is PTFE Hose?

P.T.F.E hose stands for Polytetrafluoroethylene hose. It’s a type of hose made from the synthetic fluoropolymer known as polytetrafluoroethylene, commonly referred to as Teflon. PTFE hoses are valued for their exceptional chemical resistance, low friction, and high-temperature tolerance.

Advantages of PTFE Hoses

Chemical Resistance: PTFE hoses exhibit excellent resistance to a wide range of chemicals, including acids, bases, solvents, and corrosive materials. They can withstand harsh environments without experiencing degradation or contaminating the transferred substances.

Low Friction: PTFE braided hose has an extremely low coefficient of friction, enabling smooth fluid flow and minimizing pressure drop. This property is particularly beneficial in applications where reducing flow resistance is crucial.

Temperature Resistance: PTFE hoses can handle a broad temperature range, from extremely low temperatures to high temperatures. They maintain their integrity and performance even under extreme thermal conditions.

Flexibility: PTFE hoses are highly flexible, allowing for easy installation and maneuverability. They can be routed through tight spaces and around obstacles without kinking or causing damage.

Non-Stick Surface: The Teflon braided hose possesses a non-stick surface, preventing the adhesion of contaminants and facilitating easy cleaning and maintenance of the hose.

1.PTFE Hoses: Composition, Types, and Layers

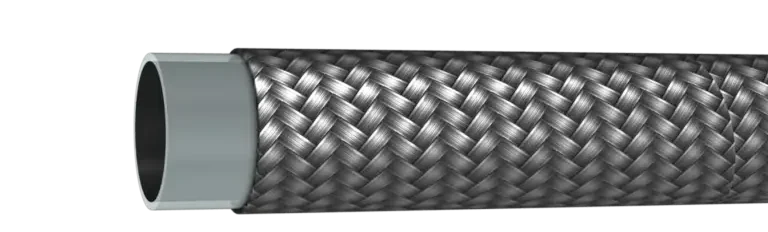

This type of hose is built for a wide array of industrial uses, including compressed gas transfer. It comes in versions designed for medium, medium-high, high, and ultra-high pressure applications. The inner PTFE core is strengthened by an external layer, typically a braid of stainless steel wire, providing enhanced durability and structural integrity. Smooth bore hoses are offered with either standard or heavy wall thickness, and are available with both non-conductive and conductive PTFE cores to manage static electricity.

A. Smooth Bore (SB) PTFE Flexible Hose:

PTFE hoses are constructed from Polytetrafluoroethylene, a high-performance fluoropolymer also widely recognized by the brand name Teflon. This material composition imparts exceptional characteristics to the hoses.

These hoses offer robust resistance to chemicals, remain inert when exposed to various substances, and withstand challenging operating conditions, including a broad temperature spectrum ranging from -200 degrees Celsius to 260 degrees Celsius. The combination of these properties makes PTFE hoses exceptionally versatile for a wide array of applications across numerous industries.

PTFE hoses are available in several configurations to suit diverse industrial needs. These include:

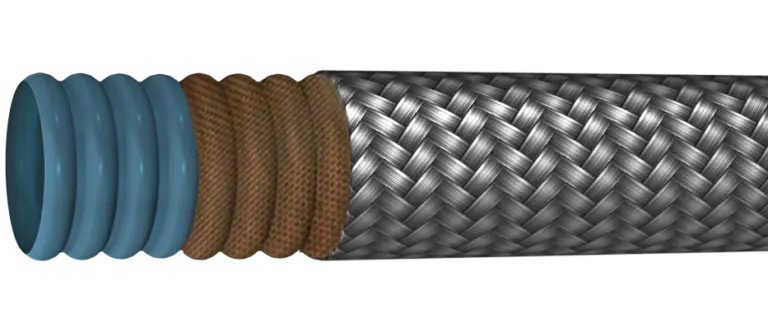

B. Convoluted PTFE Flexible Hose:

Characterized by its corrugated inner tube, the convoluted PTFE hose is offered in variants rated for vacuum or pressure applications. The vacuum-rated versions are commonly utilized in industries such as pulp and paper, automotive, turbine engines, and chemical processing. Pressure-rated convoluted hoses are ideal for chemical transfer and applications demanding high purity. The outer layer of this hose features PTFE-impregnated fiberglass reinforcement with stainless steel wires wrapped around the convolutions, and an external stainless steel wire braid further enhances its strength.

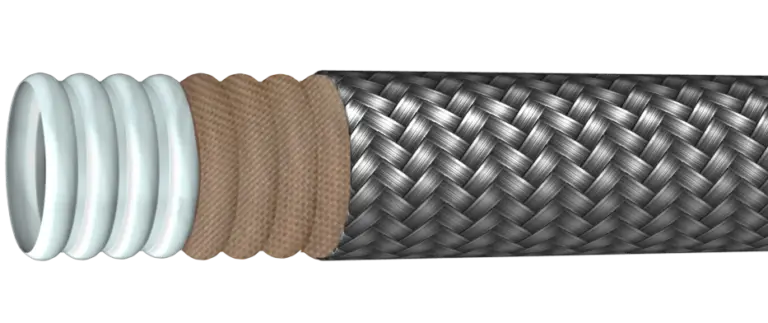

C. Chlorine Transfer Hose:

This is a specialized hose specifically engineered for the safe conveyance of hazardous substances like chlorine and bromine. The chlorine transfer hose features a helical convoluted, non-conductive PTFE core. Its outer reinforcement consists of a Kynar wire braid. The design incorporates shallow helical convolutions, which contribute to a stress-free inner core for flexibility and promote efficient draining and cleaning.

2.Benefits of PTFE across industries

Here are some of the benefits of employing PTFE hoses for handling diverse applications across various sectors:

A. Chemical Industry

Within chemical processing and manufacturing, PTFE hoses are valuable due to their capacity to convey corrosive materials and chemicals. They provide an extra layer of protection, enabling them to endure the harsh environments inherent in these applications. The use of PTFE material specifically prevents hose degradation or melting during continuous exposure to chemicals at elevated temperatures.

Key advantages of PTFE in the Chemical Industry:

- Exceptional Chemical Compatibility: These hoses can handle a vast temperature range, from -200°C to 260°C. They are not adversely affected by heat aging and are compatible with a multitude of chemicals.

- Resistance to Corrosion: PTFE hoses resist corrosion, partly because they are unaffected by UV or ozone exposure. Their design ensures compatibility with various chemicals, contributing to their anti-corrosive properties.

- Maintaining Purity: They help preserve the purity of substances being transported. PTFE is non-toxic, biocompatible, and inherently inert..

B. Pharmaceutical Industry

The pharmaceutical and medical sectors utilize PTFE due to its suitability for handling medicinal-grade substances. PTFE stands out as an excellent hose material for pharmaceutical applications that involve the transfer of diverse chemicals or related materials. Its non-reactive nature, hygienic surface, and ease of cleaning are highly beneficial. The lower coefficient of friction also makes it suitable for applications requiring minimal pressure drop or low resistance.

Key advantages of PTFE in the Pharmaceutical Industry:

- Inertness: PTFE is an unreactive material, meaning it does not readily interact with most substances. In the pharmaceutical field, inertness is paramount to prevent undesirable reactions between the hose material and medicinal solutions.

- High Hygiene Standards: PTFE hoses are produced using high-purity materials and manufacturing processes, minimizing the potential for leaching or contamination of medicinal products during transfer.

- Sterilization Compatibility: Given their wide temperature tolerance, PTFE hoses are suitable for use in heating or cooling pharmaceutical solutions. They can also be used for steam sterilization processes.

C.Automotive Industry

In the automotive sector, PTFE hoses are valued for their thermal stability and resistance to high temperatures, particularly around engine components. PTFE hoses contribute to leak-proof systems in vehicles, enhancing durability and reliability, especially at high speeds. Automobile manufacturers favor PTFE hoses due to their resistance to the corrosive nature of fuels and lubricants. Applications in this industry include use in gaskets, O-rings, fuel line linings, shaft seals, and valve stem seals.

Key advantages of PTFE in the Automotive Industry:

High and Low Temperature Resistance: PTFE hoses used in automotive applications can withstand significant temperature variations, allowing them to function effectively in both hot and cold conditions without losing their mechanical integrity.

Fuel and Lubricant Resistance: The chemical inertness of PTFE hoses makes them resistant to various fuels, including biodiesel, ethanol, gasoline, diesel, and engine and transmission fluids. This inertness prevents adverse reactions with fluids and degradation over time.

Durability: PTFE hoses demonstrate high durability and robustness when exposed to fuels. They resist aging damage effectively, maintaining their structural strength even after extended use.

D. Food and Beverage Industry

PTFE plays a crucial role in the food and beverage industry, notably as a non-stick, heat-resistant coating for cookware and various kitchen appliances like coffee makers, waffle irons, microwaves, and blenders. Its properties also make it optimal for electrical insulation, pipe coatings, seals, and liners. Hoses made from PTFE are food-grade compliant and generally more durable than alternative materials available.

Key advantages of PTFE in the Food and Beverage Industry:

Food-Grade Compliancy: PTFE’s non-toxic and inert characteristics make it a safe material for hoses that come into contact with food and beverages. A key benefit is that PTFE hoses do not release harmful chemicals into food, prioritizing consumer health.

Non-toxic and Neutral: PTFE contains no toxins and is free from any discernible odor or taste. This ensures that the original flavor of food and beverage products is preserved, meeting consumer expectations.

Effortless Cleaning: The non-stick surface of PTFE hoses simplifies the cleaning process. Residue buildup is minimal, eliminating the need for aggressive cleaning agents.

E. Aerospace Industry

PTFE hoses are installed in aircraft within the aerospace industry due to their specific attributes, including a low coefficient of friction, temperature tolerance, non-flammability, and low dielectric constant. In aircraft, PTFE hoses are used in applications such as cable insulation, fuel lines, and protecting door surfaces, among others.

Key advantages of PTFE in the Aerospace Industry:

Reduced Weight: PTFE hoses are lighter than traditional rubber hoses, contributing to better overall aircraft weight distribution. A lighter aircraft benefits from increased fuel efficiency and improved performance.

Tolerance to High Pressure: PTFE hoses are built to endure high pressures, a critical requirement for aircraft systems like fuel lines, hydraulic functions, and pneumatic systems.

Resilience in Extreme Environments: With their resistance to temperature, chemicals, and UV radiation, PTFE hoses are highly effective in enduring extreme operating conditions. Furthermore, these hoses are durable enough to withstand significant impacts and vibrations and exhibit high resistance to wear and abrasion over time.

3.Additional Advantages of PTFE Hoses

PTFE hoses offer several key advantages for handling diverse applications across numerous industries:

A. Adaptability and Simple Setup:

PTFE hoses are notably pliable, allowing them to bend and adapt easily to complex system layouts. This inherent flexibility simplifies the installation process, facilitating smooth integration into various equipment and saving considerable time and effort during assembly.

B. Smooth Flow and Enhanced Throughput

A significant benefit of PTFE hoses is their very low coefficient of friction. This property promotes unimpeded fluid movement, minimizing pressure loss and boosting overall performance. The reduced resistance ensures a high rate of flow, making them well-suited for applications where efficient fluid transfer is crucial.

C. Extended Lifespan and Reduced Upkeep:

PTFE hoses are exceptionally durable and long-lasting because of their natural resistance to wear, damage, and deterioration. Their low susceptibility to chemical, environmental, or mechanical stress means they last longer than conventional hoses, leading to substantially lower maintenance needs and associated expenses.

FAQ

Q. What types and sizes of PTFE Hose does Polyfit Industries LLC offer?

A. Polyfit Industries LLC supplies a wide range of PTFE Hose, including smooth bore and convoluted types, available in various sizes and pressure ratings to suit diverse industrial applications.