FITTINGS AND ADAPTERS

Polyfit, is a leading manufacturer of fittings and adapters crucial for hydraulic applications and industrial hose assemblies. Their range covers a wide array of connection types designed to meet various international standards and application requirements. From essential ferrules matched to specific hose constructions like SAE 100R1AT/EN 853 1SN and multi-spiral hoses, to a diverse selection of threaded fittings including NPT, BSP, JIC, and Metric in various configurations (Male, Female, Elbows), We manufacture components for creating secure and reliable fluid transfer systems. Their offerings also extend to heavy-duty connections like ORFS fittings and SAE flanges (3000, 6000, and 9000 PSI), as well as specialized items like one-piece fittings, quick-action couplings, and safety accessories.

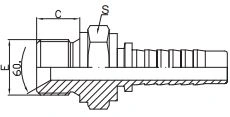

NPT

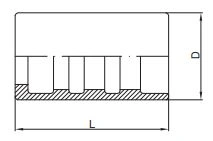

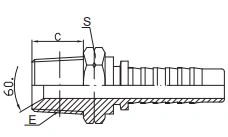

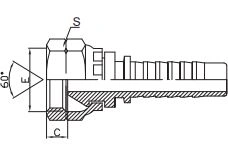

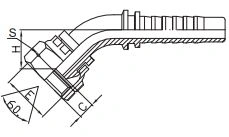

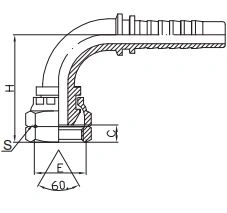

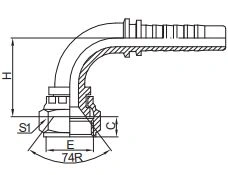

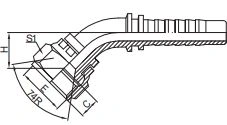

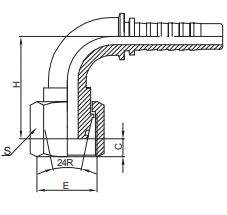

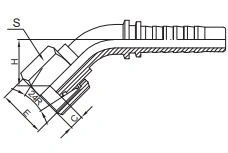

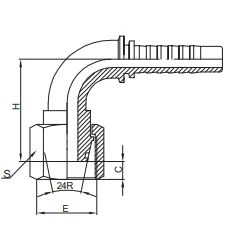

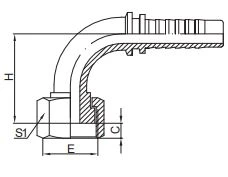

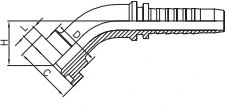

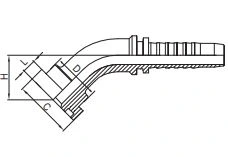

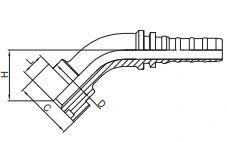

JIC

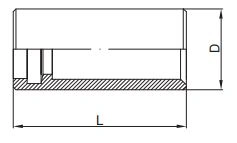

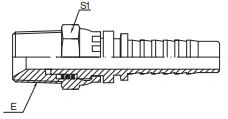

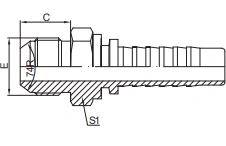

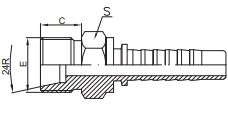

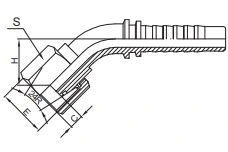

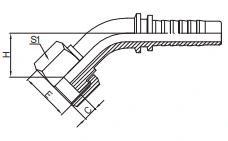

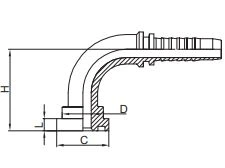

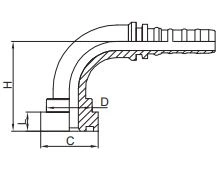

METRIC HD FITTING

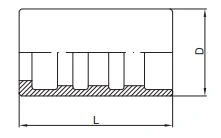

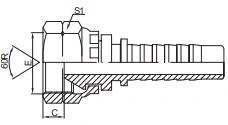

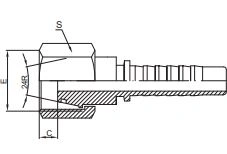

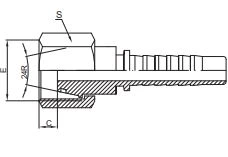

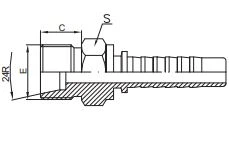

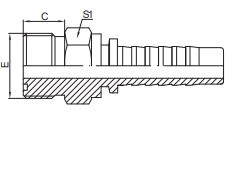

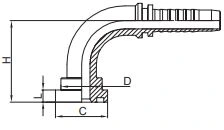

METRIC LD FITTING

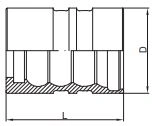

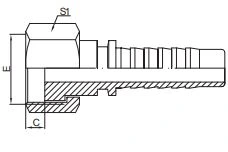

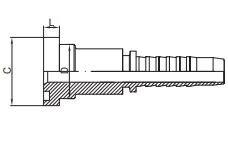

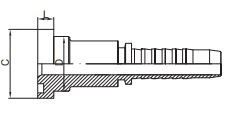

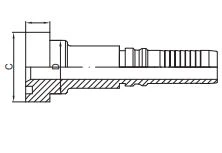

ORFS FITTING

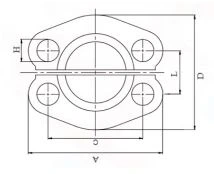

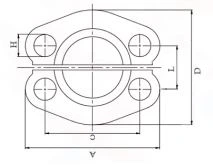

SAE FLANGE – 3000 PSI

SAE FLANGE – 6000 PSI

SAE FLANGE – 9000 PSI

One piece NPT-NPSM Fittings

One piece BSP Fittings

Ready to experience the best in Fittings and Adapters?

Contact us today – Call us at +919551955590 or email us at info@polyfit.co.in

More Info

Understanding Hydraulic and Industrial Fittings

Hydraulic and industrial systems rely on robust and leak-free connections to safely transfer fluids under varying pressures and conditions. Fittings are the components that provide these connections, joining hoses to pumps, valves, cylinders, or other hoses and system components. Ferrules, often used in conjunction with fittings, are crimped onto the hose to create a permanent and secure assembly.

The Role of Fittings and Ferrules

- Fittings: Act as the interface between the hose and the equipment. They are designed with specific thread types, sealing surfaces, and angles to ensure compatibility and prevent leaks under operational pressure. The type of fitting used depends on the port it connects to on the equipment, the hose type, and the pressure rating of the system.

- Ferrules: These are metal collars that slide over the end of the hose. When a fitting (specifically, the stem or insert) is inserted into the hose end, the ferrule is hydraulically pressed or “crimped” onto the outer cover of the hose. This crimping process compresses the hose layers and the fitting stem, creating a tight mechanical grip that holds the fitting securely in place and seals the assembly. The correct ferrule must be matched to the specific hose type and the fitting for a safe and reliable crimp.

Common Standards and Types

The variety of fittings available is largely due to different international standards and historical developments in fluid power technology. Key standards represented in Polyfit’s listing include:

- NPT (National Pipe Taper): A widely used standard in North America, featuring a tapered thread that seals by metal-to-metal interference when tightened.

- BSP (British Standard Pipe): Common internationally, available in parallel (BSPP) and tapered (BSPT) forms. BSPP often uses an O-ring or bonded seal for sealing, while BSPT seals on the threads similar to NPT.

- JIC (Joint Industry Council): Primarily used in North America, these fittings feature a 37° cone seat. The seal is created by the metal flare on the hose end pressing against the cone seat of the mating fitting.

- Metric: Fittings with metric threads and various sealing cone angles (24°, 60°, etc.). The 24° cone is common in Europe and Asia, often used with a compression ring or O-ring. Polyfit lists both Light Duty (LD) and Heavy Duty (HD) metric fittings, referring to different pressure series within this standard.

- ORFS (O-Ring Face Seal): These fittings provide an excellent leak-free connection. They feature a flat face on the female half with a groove for an O-ring. The male half has a flat face that seals against the O-ring when connected.

- SAE Flange: Used for larger sizes and higher pressures, these connections involve a bolted flange where an O-ring trapped between the two flange faces provides the seal. They are categorized by pressure ratings (3000 PSI standard duty, 6000 PSI heavy duty, and 9000 PSI extra heavy duty).

Polyfit’s Fittings Product Range Details

Polyfit’s offerings cover a broad spectrum, ensuring they can meet the diverse needs of their clients in the UAE.

Ferrules for Various Hose Constructions

Polyfit supplies ferrules specifically designed to match common hydraulic hose constructions as defined by SAE and EN standards. This is critical because the dimensions and reinforcement layers vary between hose types, requiring a correctly matched ferrule and crimping process for a safe assembly. Their range includes ferrules for:

- Single wire braid hose (SAE 100R1AT / EN 853 1SN)

- Double wire braid hose (SAE 100R2AT / EN 853 2SN)

- Four spiral wire hose (4SP / 04-10 size range)

- Four or Six spiral wire hose (4SH / 12-32 size range, R12 / 20-24 size range, R13)

- Thermoplastic hoses (SAE 100R7, SAE 100R8)

- Teflon (PTFE) hoses

Standard Threaded Hydraulic Fittings

Their selection of threaded fittings covers the major international standards used in hydraulic systems:

- NPT: Available in common NPT Male and NPSM Female (with a 60° cone seat, often used with NPT male).

- BSP: Includes BSP Male with O-Ring seal (BSPP type) and BSP Female with a 60° Cone seat (compatible with BSPT male or some BSPP male adapters). They also offer 45° and 90° elbow configurations for routing flexibility.

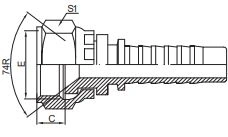

- JIC: Features JIC Female with a 74° Cone Seat and JIC Male with a 74° Cone Seat, available in straight, 45°, and 90° configurations.

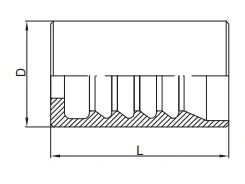

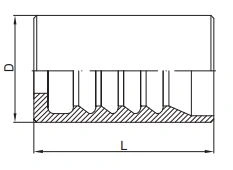

- Metric: Provided in both Heavy Duty (HD) and Light Duty (LD) series, featuring Metric Female and Male connectors primarily with a 24° cone seat, also available in straight, 45°, and 90° elbow shapes.

One-Piece and Specialty Fittings

Polyfit also highlights “One piece” fittings, which integrate the ferrule and fitting body into a single unit, potentially simplifying the crimping process for compatible hoses. They list one-piece versions for JIC 37° flare, NPT/NPSM, and BSP fittings in various swivel and rigid configurations, some with specific product codes like PF-43-xxxx-SS (indicating stainless steel likely).

High-Pressure and Seal Types

For applications requiring superior leak resistance or higher pressure capabilities, Polyfit offers:

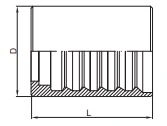

- ORFS Fittings: Featuring ORFS Female connectors with a flat seat and ORFS Male with an O-Ring seal, available in straight, 45°, and 90° elbows.

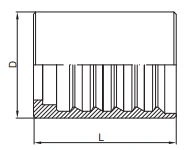

- SAE Flanges: Heavy-duty bolted connections available in the 3000 PSI, 6000 PSI, and 9000 PSI pressure classes, including the necessary split flange clamps for secure mounting.

Industrial and Safety Accessories

Beyond standard hydraulic fittings, Polyfit supplies components for broader industrial hose applications and safety:

- Macdonald Type Quick Action Coupling: A specific type of quick disconnect coupling.

- Boss Steam Hose Fittings: Designed for high-temperature steam applications.

- Industrial & Composite Hose Fittings: A broader category covering fittings for various non-hydraulic industrial hoses.

- Whip Check: Safety cables used to restrain hose assemblies in case of a coupling failure, preventing dangerous “hose whip.”

- Water Blast Quick Coupling SS – 15k: Very high-pressure quick couplings suitable for water blasting applications (rated up to 15,000 PSI), likely in stainless steel (SS).

- Air Breathing QRC: Quick release couplings specifically designed for air breathing apparatus, ensuring a secure and reliable connection for life support.

FAQ

Q: What are hydraulic and industrial fittings used for?

A: Hydraulic and industrial fittings serve as connectors used to join hoses, tubes, and pipes to various components within a fluid transfer system, such as pumps, cylinders, valves, and ports. They are essential for creating sealed pathways that can safely transport fluids, often under high pressure, in applications ranging from heavy machinery and manufacturing to oil and gas and construction.

Q. Why are ferrules necessary when making hose assemblies?

A. Ferrules are crucial components used in the crimping process of hose assemblies. They are placed over the end of the hose before the fitting stem is inserted. When the assembly is crimped using a specialized machine, the ferrule compresses the outer cover and reinforcement layers of the hose onto the fitting’s stem, creating a strong, permanent mechanical grip and a leak-tight seal capable of withstanding the system’s working pressure. Using the correct ferrule matched to the specific hose and fitting is vital for safety and performance.

Q. What do standards like NPT, BSP, JIC, and Metric signify in fittings?

A.These acronyms represent different international standards for fitting thread types and sealing methods.

- NPT (National Pipe Taper): A North American standard where tapered threads create a seal by interference.

- BSP (British Standard Pipe): An international standard with parallel (BSPP) or tapered (BSPT) threads. BSPP often seals with an O-ring or bonded seal, while BSPT seals on the threads.

- JIC (Joint Industry Council): Common in North America, featuring a 37° flare cone seat for a metal-to-metal seal.

- Metric: Uses metric threads, often with a 24° cone seal, prevalent in Europe and Asia. These standards ensure compatibility between components from different manufacturers and are critical for proper sealing and system integrity.

Q. Who supplies hydraulic and industrial fittings and adapters in the UAE and GCC?

A. Several suppliers operate in the UAE and across the GCC region, offering a wide range of hydraulic and industrial fittings and adapters. One such supplier is Polyfit, based in the UAE, who provides a comprehensive selection of ferrules, threaded fittings (NPT, BSP, JIC, Metric), ORFS, SAE Flanges, one-piece fittings, and various industrial couplings and accessories. Other companies in the region also specialize in fluid transfer products and hose assembly components.

Q. What is the difference between ORFS and SAE Flange fittings?

A. ORFS (O-Ring Face Seal) fittings use an O-ring compressed between a flat female face and a flat male face to create a very reliable, leak-resistant seal, typically used in hydraulic lines. SAE Flange fittings are bolted connections, generally used for larger hose sizes or higher pressures, particularly in heavy equipment. They utilize an O-ring seated in a groove on one flange half that seals against the mating flange face when the connection is bolted together. SAE Flanges are further categorized by pressure ratings like 3000 PSI, 6000 PSI, and 9000 PSI.